NPK compound fertilizer contains two or more kinds of macroelements, which can provide rich nutrition for the growth and development of soil and plants. What should be paid attention to when applying NPK compound fertilizer?

There are different concentrations of compound fertilizer, we should pay attention to choose the appropriate concentration. At present, most compound fertilizers are distributed according to the average nutrient status of soil types and the proportion of fertilizer required by crops in a certain area. There are high, medium and low concentration compound fertilizers on the market.

How to make npk compound fertilizer granules? Go to https://fertilizerplantequiment.com/compound-fertilizer-production-line/

Generally, the low concentration of total nutrients is between 25% ~ 30%, the medium concentration is between 30% ~ 40%, and the high concentration is more than 40%. And crops. Generally speaking, high concentration compound fertilizer is used for economic crops with good quality, less residue and high utilization rate. The concentration of compound fertilizer is high. Avoid direct contact between seeds and fertilizer. The nutrient content of compound fertilizer is high. If the seeds or seedling roots are directly contacted, the emergence of seedlings will be affected, and even the roots will be burnt. When sowing, seeds should be mixed with acupoints, and compound fertilizer should be applied in strips with an interval of 5-10 cm.

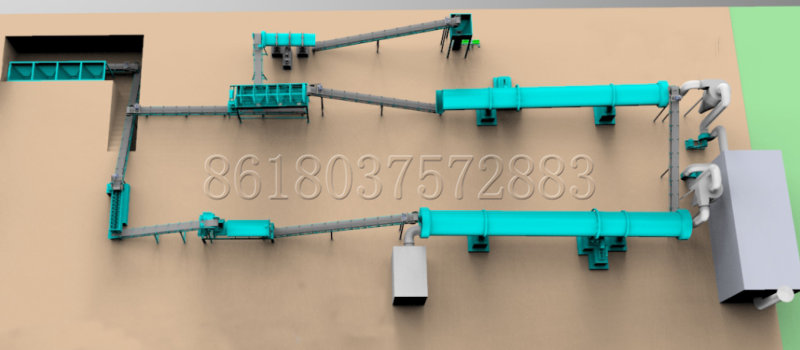

NPK Drum Granulation Line

Matters needing attention in application of NPK compound fertilizer

It is necessary to pay attention to the nutrient composition of compound fertilizer with different proportion of raw materials. Different brands and concentrations of compound fertilizer use different raw materials, which should be selected and used according to the types of soil and crops. The compound fertilizer containing nitrate is not suitable for leaf vegetables and paddy fields. It is not suitable to use compound fertilizer containing ammonium ion, potassium chloride or chloride ion in saline alkali soil, potassium sulfate in crops or saline alkali soil, and potassium sulfate in paddy field and acid soil, otherwise it will reduce fertility and even poison crops.

The compound fertilizer containing two or more kinds of large elements is easy to volatilize or lose with the rain, and the phosphorus and potassium are fixed by the soil, especially the mobility of phosphorus in the soil is small, and it is not easy to be absorbed. The crop root system is on the surface, which is not conducive to deep root system. The drought condition in the fertilizer can not be dissolved, and it is worse in the development, so the compound fertilizer should go deep into the soil.

Find machines to make your own fertilizer? Go to https://fertilizerplantequiment.com/