The effect of organic fertilizer was slow, and the effect of topdressing was not as obvious as that of base fertilizer before sowing or transplanting.

When is organic fertilizer usually applied? For greenhouse growers, organic fertilizer should be applied before soil sterilization.

To make fertilizer by your own from organic manure wastes, go to https://organicfertilizerplants.com/

(1) The organic fertilizer which is not completely decomposed will rot further after being treated in the closed shed.

Application time of organic fertilizer

(2) The pathogenic bacteria, diseases and insect pests and other harmful microorganisms in organic fertilizer are basically killed after high temperature and expansion treatment, and no longer do harm to crops.

large scale wheel type compost turning machine

(3) Expired microbial fertilizer and bio organic fertilizer should also be used before disinfection in the soil closed shed to prevent bacterial contamination of the soil after disinfection.

To recycle animal manure as raw materials for organic fertiizer production, go to https://organicfertilizerplants.com/animal-manure-compost-production/

How to apply organic fertilizer?

The main function of organic fertilizer is to improve the soil, so it should be combined with deep ploughing to make the soil and organic fertilizer completely mixed. It can also be combined with soil conditioner to improve soil environment, balance nutrition and increase soil aggregate structure.

In addition, the quality of organic fertilizer is also a factor affecting the raw materials, equipment and production line in the process of organic fertilizer production.

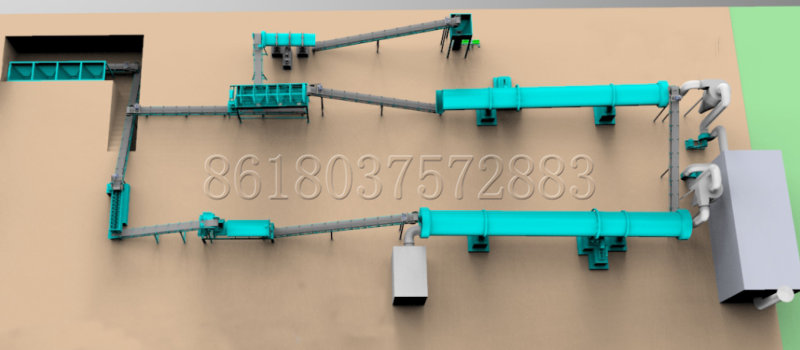

We are a fertilizer production machinery factory covering an area of about 13000 square meters. We have 30 high-quality talents and 70 professional workers. Since 2010, we have been providing OEM services to our customers. We have a strong technical force, high-quality staff and R & D, design, manufacturing team. We provide customers with process design, equipment manufacturing, installation and debugging, the whole one-stop service.