With regards to separating solids and liquids, you will require specialized equipment to accomplish this method. This could be used in the chemical and mineral industry. For example, water treatment plants should have machines that may separate chemicals and minerals in the water. This is just what allows them to purify the water to be utilized for public consumption. There are several elements of this procedure that has to are employed in tandem. Including the use of the filter press, a centrifugal component, effective at cleaning base metals and chemicals in the water. This is what you should know about the most up-to-date varieties of solid-liquid separation equipment which can be that you can buy.

How Are These Machines Typically Used?

In most cases, these are used for drying animal manure. You will likely have a great flow of water arriving, that will pass through separate filters, that may eliminate the contaminants. From mineral content, to waste matter, this could be filtered out. There is usually a centrifugal process involved. This could include filtering centrifuges, or sedimentary centrifuges, that you can use for this particular process.

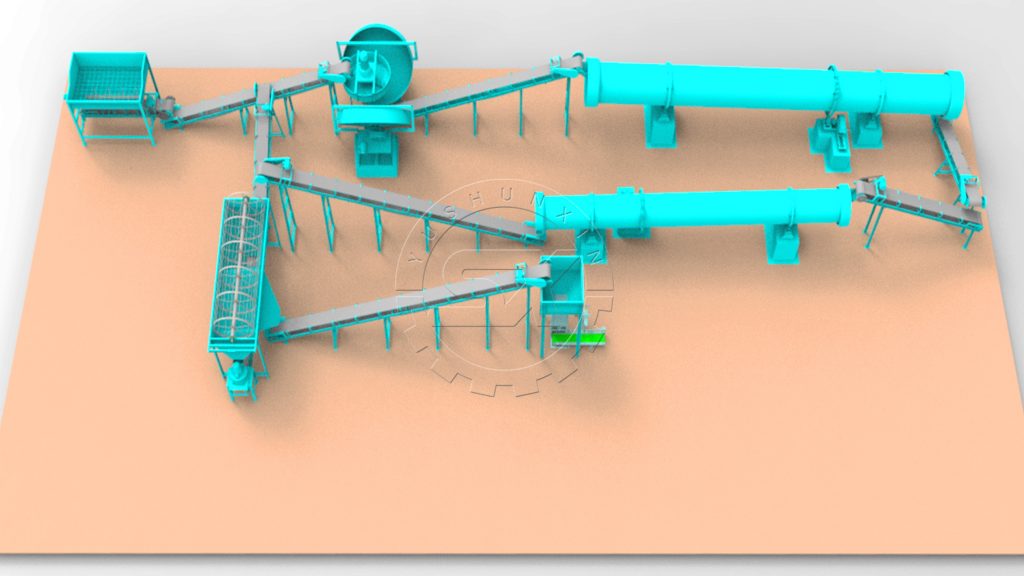

Dehydrating machine for large-scale composting plant

Different Parts Of These Appliances

In modern machines, there exists always a personal computer involved. There will be a series of sensors which will be utilized to monitor the entire process. The ceaseless temperature flow circuit, the control algorithm, as well as the valve controls will be section of the system itself. This will be connected in some way to your compressor, and filtration system, that will do the work. The level of separation of animal manure really depends on just what the water will probably be utilized for. This can be used as filtration, microfiltration, or even the reverse osmosis process. Regardless of the system which is used for filtering the fabric, it is really an elaborate procedure that requires multiple components and computer systems to observe the process.

fertilizer making machine for drying animal manure

How To Locate Machines That Can Try This

To locate companies that produce these machines, it’s very easy to perform. It can just take a few momemts of the time. You will find suppliers of solid-liquid separation machines, many of which works extremely well at facilities such as mining operations, farming operations, and more. You may compare the many sizes of your machines, precisely what the output will likely be, and just how much they may cost. This information can be found from the companies within a few minutes by contacting them directly. These can prove to be one of the more valuable assets to your business, especially nowadays in this fertilizer production industry.

When you may need an excellent-liquid separation machine, you will find this equipment for sale online. Right away whatsoever, It will likely be delivered to your facility, set up, and completely functional. This will allow you to separate solids from liquids on a continual basis. This could be needed if you are producing fertilizer. Just be certain that it comes from a manufacturer that is known for producing quality solid-liquid separation equipment.