There are numerous several types of fertilizer that one could purchase for your farm. Of these, NPK fertilizer is considered the most useful. Its content has a great deal of nitrogen, potassium, and also much-needed phosphorus that can help produce crops that are extremely healthy and viable. To accomplish this, you will need to have the machine that may make the pellets. They are called NPK granulating machines. Though they are made differently, their main goal or objective is going to be achieved once you know how to use the proper granulator for producing NPK granular fertilizer.

So How Exactly Does An NPK Fertilizer Machine Work?

The method starts with getting a large number of potassium salt. This needs to be melted, developing a very aqueous solution. This will likely also contain a great deal of ammonium nitrate. This is why the nitrogen will come from within this mixture. Finally, ammonium phosphate will be the final ingredient. This will likely allow the phosphorus that can complete this triune combination. The ultimate area of the process is actually using this mixture and combining it together. The outcome will probably be granules of most three of those components that may create NPK fertilizer.

NPK fertilizer granulating mahcine

How Come This Fertilizer So Essential?

The primary reason that the particular kind of fertilizer is really useful is primarily due to nitrogen. Of course, the mix of all three is going to improve crops dramatically. There are various crops that may extract these three nutrients in the soil. However, it really is nitrogen that is generally probably the most depleted away from these. For this reason many farmers will rotate crops that may not merely use more phosphorus and potassium, but may as a byproduct inject more nitrogen in to the soil. Rather than rotating crops, however, farmers are more inclined to easily place NPK fertilizer in the soil to fix the problem.

How To Locate NPK Fertilizer Machines

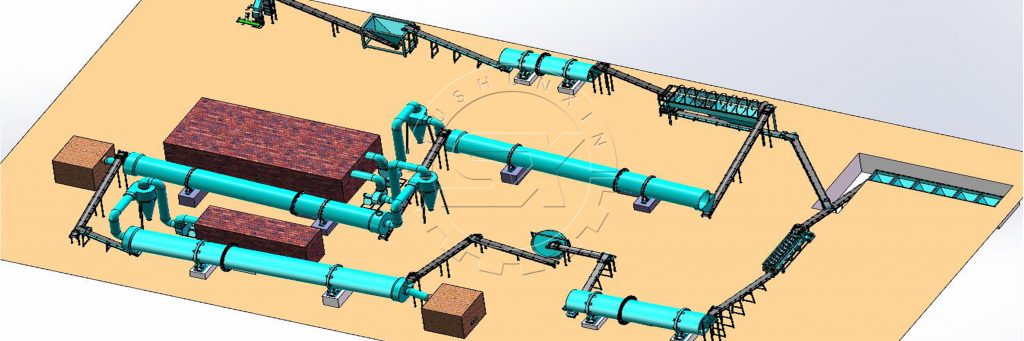

The final area of the process is the creation of granules. This typically occurs inside the NPK rotating drum. There can also be a fertilizer dryer, fertilizer mixer, and a coating machine which will apply material on the exterior in the pellets. It’s important too to get the machinery that will be needed before this technique occurring. This will likely add a fertilizer crusher and compost turner to name a few. Because the NPK fertilizer drum actually starts to rotate, it will make the pellets of fertilizer rapidly. All of this has made it feasible for big-scale farming operations to go on every single year.

The design of NPK fertilizer production line

If you wish to purchase an NPK fertilizer granulating machine, you have to get multiple estimates from as much companies as you possibly can. Many of them will be positioned in other countries where the expense of producing them is less. This will likely be the ideal source of these machines. Not only can they become more affordable, but they are produced by businesses that were which makes them for years. The improvements who have gone into creating these machines, and also the more affordable prices, may motivate you to have a number of of these this season for the business.