In case you are converting manure into fertilizer, you may want to prepare it for storage. You may convert this product into pellets that can be placed into bags or containers. This material can be used with time, and in many cases sold for some other companies, to use on his or her crops. These machines come in several forms and sizes. It is also easy to produce both wet and dry versions of these fertilizer granules. This is the way you will find probably the most inexpensive fertilizer granule machines available on the market.

What Exactly Is The Main Objective Of The Machines?

The primary purpose is usually to make granular fertilizer as possible with the existing materials. If you have a farm with animals, and they are producing a large amount of waste material, this can be used for producing fertilizer pellets. This is the conversion process that is simplified when you use these appliances. The capability to rely on them regularly will help you maintain stocks of all the fertilizer required for your small business.

What Do Fertilizer Granule Machines Do?

In general, they are machines made for one purpose. That is certainly for taking raw materials, convert them into a pelletized form, hence they can be used as fertilizing both large and small crops. One of the more popular is NPK fertilizer granules that feature a large abundance of nitrogen. It will contain potassium and phosphorus. These materials can be easily included with the soil, providing the nutrients essential for most crops that happen to be grown today.

chicken manure fertilizer granules

Just How Do They Work?

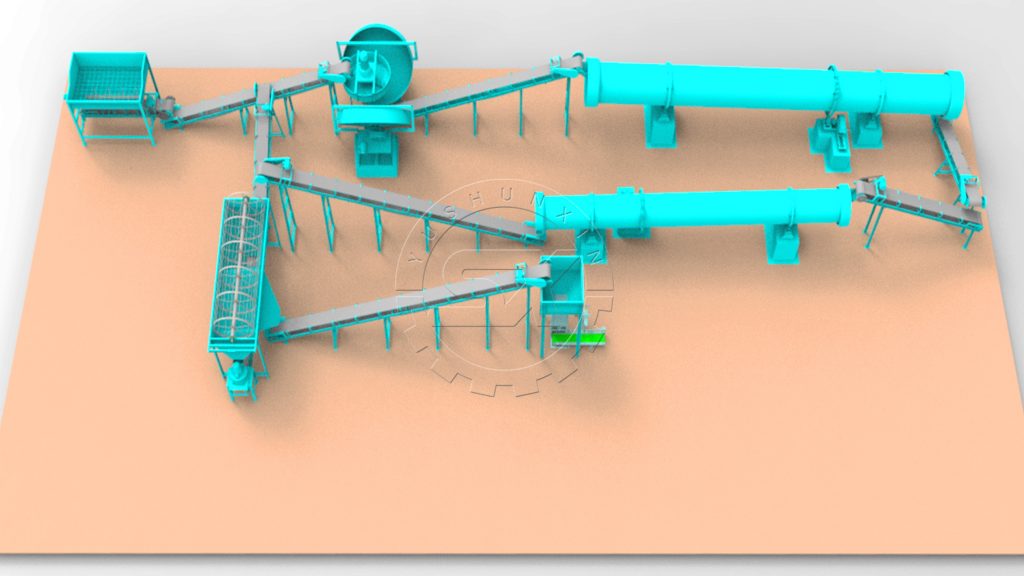

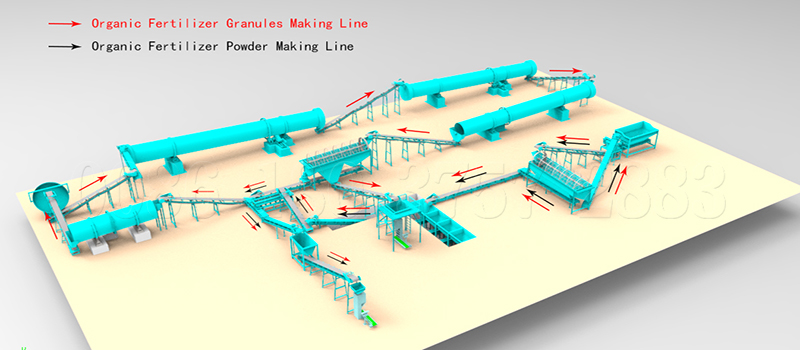

One of the more popular models is really a rotating drum fertilizer granulator. These are designed for both low to high fertilizer production. It really is from the motion in the drum itself how the pellets might be produced. The rotation will make up the material into balls, which will be elongated, and subsequently solidified into pellets. There are various types that you can use including granulator machines that may work with a compost turning device. There is likewise associated screening, cooling, and drying machines. Packing machines will likely be needed once the process is complete.

How To Get The Best Deals About Them

The most effective deals usually result from businesses that are greater than most. Their ability to discount these products is less difficult as opposed to those with much smaller quantities of output. Most larger businesses make their profit based on the amount of sales. That is why employing a large company, preferably one having the ability to produce these machines at a lower price, could be your primary objective. They can save you money, and in addition connect you using the latest granulator machines available.

fertilizer granulating machine for sale

You can find these businesses online. Speaking to each manufacturer, you can obtain a summary of their latest models. The costs will be stated, along with specifications based on how each of them works. This data is invaluable, providing prospective buyers together with the knowledge they will have to make the right decision. In case your farm is big, or if you simply want another machine at your disposal, you can save money by getting one of these brilliant newer units. It’s always possible to talk to fertilizer granulating machine manufacturers that will give you inexpensive prices around the latest fertilizer granule machines available today.

The important thing for an individual to do organic fertilizer is to find a market, but also to find low-cost raw materials. Generally, the price of raw materials is relatively low in places where there are more farms, and even some farms are busy with the farming industry. The problem of manure disposal is difficult to solve. As long as they can help them deal with manure, they are willing to give it to you in vain. In this case, the

The important thing for an individual to do organic fertilizer is to find a market, but also to find low-cost raw materials. Generally, the price of raw materials is relatively low in places where there are more farms, and even some farms are busy with the farming industry. The problem of manure disposal is difficult to solve. As long as they can help them deal with manure, they are willing to give it to you in vain. In this case, the