The construction scale of general organic fertilizer production line configuration is generally 5000 tons-100,000 tons per year. It is necessary to comprehensively consider local resources, market capacity, and market coverage.

What is the cost of fertilizer production equipment?

The equipment investment scale and product selection plan of the manure organic fertilizer production line need to be formulated according to the following conditions: raw material resource characteristics, local soil conditions, local planting structure and main crop varieties, and comprehensive consideration of local resources, market capacity, and market coverage radius. Generally, small new factories can produce 10,000 tons (1.5-2.5 tons/hour), 20,000 tons (2.5-3.5 tons/hour), and 30,000 tons (4.5-6 tons/hour) per year. Medium-sized factories are producing 3- 50,000 tons, large factories are producing 50,000-100,000 tons per year. The investment scale and the design of the production line plan need to be formulated according to the characteristics of raw material resources, local soil conditions, local planting structure and main crop varieties, factory site conditions, and the degree of automation of production.

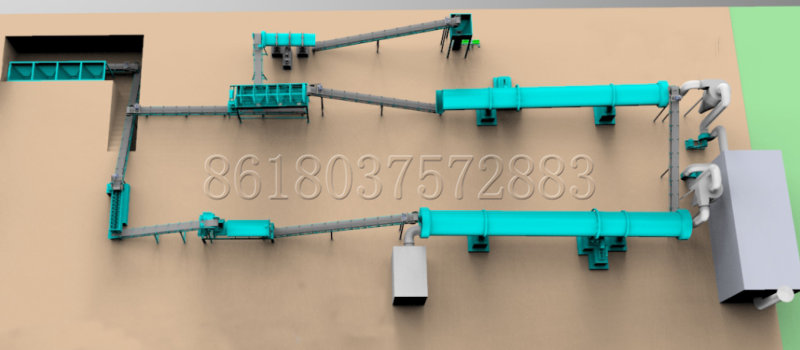

What configurations of the organic fertilizer production line can I buy?

The manure organic fertilizer production line has three configurations: high, medium and low. Large fertilizer plants must adopt a complete set of production configurations, and the appearance and nutrient content of the finished products can meet the market requirements, and they have a greater advantage in the promotion of finished organic fertilizers. The low-to-medium configuration organic fertilizer production line is suitable for small and medium-sized fertilizer factories. The sales scope of finished organic fertilizer is limited to nearby areas. Some processes in the organic fertilizer production process need to be completed manually.

How do I select the fertilizer machines according to the amount of raw materials?

If the daily production of animal manure exceeds 5 cubic meters, and the maximum amount does not exceed 10 cubic meters, you can purchase simple facilities, mainly mobile turning machines (turning machines), shredders and other facilities, and the cost of investment facilities needs 15,000 to 45,000 USB. Yuan. If the daily production of livestock and poultry manure exceeds 10 cubic meters, more equipment is recommended. Generally, an investment of 45,000 to 90,000 USB is required, and a complete set of equipment may cost more than $150,000.

What production site is suitable for my organic fertilizer production plant?

Generally, planning principles of site selection: close to raw materials, convenient site transportation, good infrastructure, try to use the original buildings, reduce the scale of investment, increase the efficiency of capital use, and give full play to the demonstration function of the project. Stay away from residential areas and choose down vents; adapt measures to local conditions, arrange compactly, and make use of abandoned land as much as possible: separate living areas from the factory site and maintain environmental sanitation.