For those who have a substantial amount of cattle on your property, it really is easy to make fertilizer to your crops. This is a very robust kind of compost that may be created in the span of just a few months. Combining this with fillers, you can create pellets that can be used to fertilize your crops quickly. Storing the leftover fertilizer pellets is feasible, or sell those to other farms in the community. Here is an introduction to the entire process of making cattle manure fertilizer. It’s actually less difficult than you would imagine.

Creating Your Compost Pile

Before fertilizer can be produced, the compost has to be produced. This originates from the manure that you are likely to collect. This can be accomplished manually, or you can have machines that will collect the cow manure. This will then be placed right into a pile. Our recommendation is that you make a coe dung pile, measuring no less than 4 ft.² in proportion. If it’s larger, it might take longer for the piles of compost due to level of chemical reactions that must occur within that material. Be sure to add no less than 3 inches of organic material, accompanied by the compost, giving the procedure an enhancement. It should be turned over, at least every 72 hours, to exacerbate the chemical changes that will happen to create the compost from the manure.

Wheel type composting machine for cattle manure

How You Can Know The Procedure Is Over

There will be a large amount of heat which will be generated through this chemical process. In reality, once the heat starts to minimize, you will be aware that it is coming to the final stages of your process. Most of the heat is going to come from the centre of the pile. By inspecting it, you are able to tell if it is easy to crumble, and in case it offers now created a dark brown hue. One other aspect to consider is the smell. It would often have a very earthy odor. Once this can be done, after that you can start to use machines that can take this compost and produce cow dung fertilizer pellets.

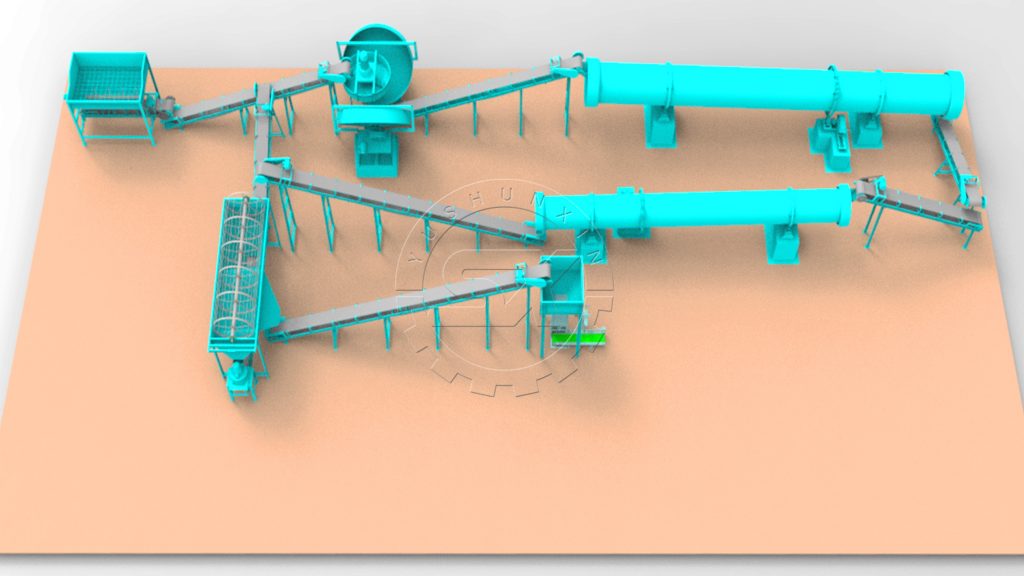

Machines Which Could Compost Pellets

These are typically typically known as a fertilizer granulators for cow dung. They can be either a big tube with multiple holes. Or it will likely be a circular disc platform with edges. As being the material rotates, it will probably be forced out through openings, creating the development of the pellets. This will likely then be paid by material that will solidify round the exterior. This may ensure that the compost is just not decompose early. All this can be achieved inside the span of just a few months you will find the proper setup on your facility.

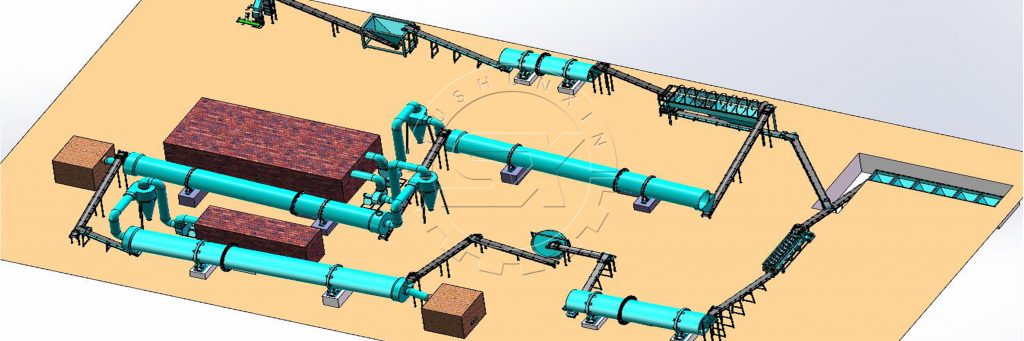

rotary drum granulator for cow dung

Although this may take many months to complete, the whole process of creating fertilizer from cow manure is pretty straightforward. You should have machinery to collect the cow manure, stack it, and ultimately process the pellets that will make the fertilizer. It is much less expensive to accomplish it all by yourself. However, there are expenses that you need to consider before attempting this by yourself. The primary price is higher, but during the period of a few months, and certainly over many years, you are going to save money by producing compost from cattle manure.