Considering Different Kinds of Fertilizer Granule Machines to create Organic and Compound Fertilizer

If you’re comparing different kinds of fertilizer granule machines to generate organic and compound fertilizer, you’ll desire to make sure you’re focusing on the proper factors. You should ensure you’re able to measure the equipment in your own cost range so that you can come up with a smart purchase.

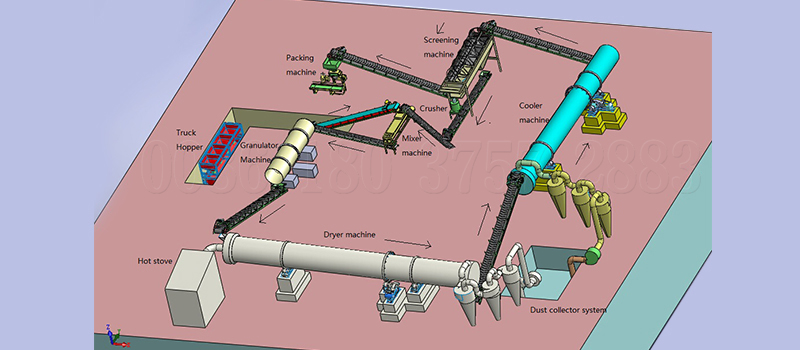

Consider the Design of Your Production Line

To start out, you’ll want to consider the design and design of your production line. In case you have a clearer picture of the organic granulator may be like and the way it will operate, you’ll manage to find granule machines that work well well in that line.

It’s best to test out different layouts before purchasing any equipment. Doing this, you can try various layouts without needing to move heavy equipment. It is possible to select your ideal layout and possess the equipment place appropriately once it arrives.

disk granulation line for making organic fertilizer

Buy from a Vendor and Brand You Trust

You’ll want to ensure that you have total confidence in the caliber of the machinery that you’re purchasing. It’s crucial that you know you can trust the vendor you’re buying organic fertilizer granulating equipment from, and you’ll would also like to make sure you buy equipment that had been manufactured by a manufacturer you already know you can be determined by.

You won’t want to suffer from complications with your equipment later down the line. You must be able to inquire and gather valuable information before your purchase. You must also recognize that the producer behind your equipment features a good reputation for quality.

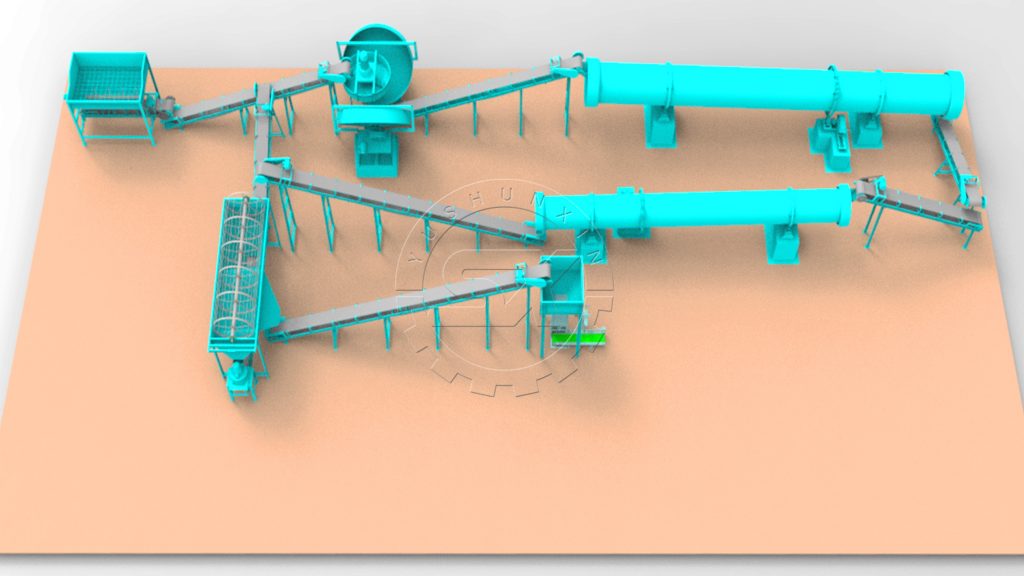

Center on Newer Models

You don’t necessarily must purchase one of several latest models of organic fertilizer granulating machines on the market, but you can find distinct benefits to buying newer equipment. While the base purchase price may be higher, you may even realize that you’re getting better value in the equipment you’re buying overall.

Newer models tend to be more energy-efficient than older models. In addition to that, many newer models come with features that make them easier to work with. With a new model, you can also imagine that maintenance won’t be the maximum amount of of the issue.

organic fertilizer granulating machine

Estimate Operating Costs

What will it cost to keep your fertilizer production line working? You must do your best to estimate these costs prior to your purchase. If there are high expenses associated with a specific granule machine that you’ve been looking at, you’ll want to make certain that you’re aware about these costs upfront.

Your operating costs can have a direct impact on your profits, which explains why you’ll want to make certain that the fee for running your production line is very manageable. Don’t overlook the fee for future repairs when you’re making these estimates.

By comparing and contrasting different varieties of organic fertilizer granule machines to make organic and compound fertilizer, it is possible to weigh your choices and look for the optimal equipment to your production line. Whatever form of machinery you ultimately choose, you’ll have the capacity to gather plenty of valuable information in front of your purchase.