Bio organic fertilizer is a kind of commercial fertilizer, which is composed of special functional microorganisms, chicken manure, duck manure, cow manure, sheep manure, crop straw and so on. It is harmless in the production process of organic fertilizer.

1. In the production process of bio organic fertilizer from Sheep manure, the factors that affect the fermentation of organic waste and microbial reproduction must be effectively controlled. The main factors affecting the organic matter content, moisture content, C / N ratio, oxygen concentration, temperature and pH value in composting process.

On the one hand, through the control of various factors, it can meet the carbon nitrogen ratio, temperature, humidity, pH value, oxygen content and other nutrients necessary for the growth and reproduction of various microbial strains. On the other hand, different nutrient contents will produce different fertilizer effects.

For example, high carbon content is conducive to the increase of soil fungi, while nitrogen is conducive to the increase of soil bacteria. Calcium has an obvious effect on the disease resistance of crops.

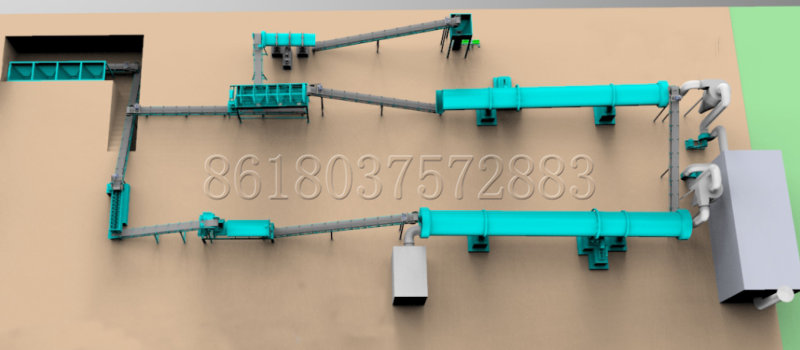

Production technology of organic fertilizer

2. The odor produced by composting must be prevented and controlled to avoid secondary pollution. Adding starter or rapidly decomposing bacteria to the compost can reduce the odor in a short time, and the compost turning machine is used to treat it by biological deodorization technology.

3. The basic components of bio organic fertilizer, organic fertilizer and chemical fertilizer are almost the same. The difference is that there is no biological flora in organic fertilizer. Bio organic fertilizer takes bio organic fertilizer as carrier. After pelletizing, the product can increase soil nutrients and beneficial bacteria, improve soil activity, improve microbial flora, inhibit the growth of harmful pathogenic bacteria, inhibit the occurrence of diseases, and improve crop quality and yield.