In recent years, China has made great efforts to develop animal husbandry and put forward zero growth of chemical fertilizer consumption. These policies are undoubtedly a big push for animal husbandry. On the other hand, it is suggested to protect the environment, reduce aquaculture emissions and recycle aquaculture emissions. How to reduce agricultural pollution emissions and increase the recycling of aquaculture resources?

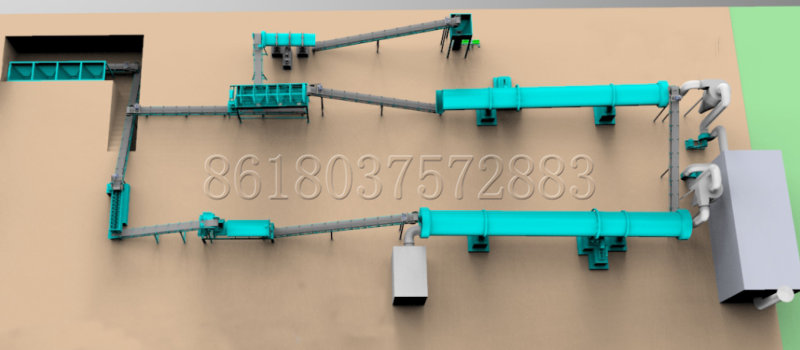

In short, it is necessary to use the organic fertilizer equipment to transform the planting pollution into organic fertilizer, and apply the organic fertilizer back to the crops to realize the complete recycling.

So the purchase of organic fertilizer equipment becomes very important, and the appropriate equipment is very important for the production of organic fertilizer. Here are some tips on how to buy organic fertilizer equipment for you:

1. Determine the size of the equipment: for example, how many tons per year, or how many tons per hour, or how many tons per day?

2. Determine whether the production is powdery or granular organic fertilizer. The investment of powder equipment is generally small. The main equipments include premixing equipment, turnover equipment, refining equipment, organic fertilizer powder packaging equipment, belt conveyor, etc. If the particle is selected, it depends on the shape of the production, whether it is standard spherical or irregular. It depends on the local fertilizer market and farmers’ consumption habits.

3. The choice of granulator, if it is to produce standard spherical granulator, disc granulator, drum granulator, wet granulator, organic fertilizer rapid granulator and so on, all these need supporting drying equipment; If columnar granule is selected, the main equipment includes flat mould granulator, ring mould granulator, etc; If the oblate ball is selected, the main equipment is the roller type extrusion granulator, so there is no need to dry during production. Can use the machine, equipment design is relatively simple.

4. Determine the configuration of equipment: different configuration level, different equipment price, different labor, different production environment.

5. Determine the type of fertilizer to be produced. There are four kinds of organic fertilizer: pure organic fertilizer, organic-inorganic compound fertilizer, biological organic fertilizer and microbial compound fertilizer.

The equipment is different. Pure organic fertilizer has strong adaptability and can be produced by general equipment. Organic and inorganic compound fertilizers depend on different fertilizer formulations. If the total nutrient content is high, the selection of granulator is more demanding.

6. Selection of fermentation overturning machine: General fermentation forms include strip fermentation, shallow fermentation, deep tank fermentation, organic fertilizer fermentation tank, tower fermentation and barrel fermentation. Different fermentation methods and fermentation equipment are different. Generally, the shallow tank turnover machine is more suitable for the principle of aerobic fermentation, and the price is not high, so it is more suitable for the actual situation.

More details, welcome go to https://organicfertilizermachines.com/