The chicken manure dryer is an instrument used for the processing and drying of chicken manure, which can improve the environment of the chicken farm and increase the utilization rate of chicken manure. Pure chicken manure organic fertilizer is based on fresh chicken manure as the main raw material. It is refined after thorough de-dusting, purification, high-temperature drying, concentration and crushing, disinfection and sterilization, decomposition and deodorization. It contains a variety of nutrient elements required by crops. It is confirmed by relevant experts that the nitrogen content is 2.6%, the phosphorus content is 3.5%, the potassium content is 2.5%, the crude protein is 16-25%, and the organic matter is 45%.

Chicken Manure Dryer

Chicken manure dryer equipment play a great role in chicken breeding companies. After large-scale experiments, 100Kg fertilization per mu of wheat can increase yield by more than 20%, vegetable fertilization 100Kg per mu can increase yield by more than 30%, fruit tree fertilization 25Kg can increase yield by more than 40%, and watermelon fertilization 100Kg per acre can increase yield by more than 40%. No longer use other fertilizers. The organic fertilizer is a yellow-brown uniform granular product with little pollution, no odor, easy to use, and high fertilizer efficiency, which is beneficial to improve the soil and overcome the salt-alkali damage caused by long-term use of chemical fertilizers. It is suitable for wheat, rice, peanuts, melons and fruit trees and other crops to improve the quality of crops, improve the quality of melons and fruits, and is beneficial to human health. It is a good-quality fertilizer for the cultivation of pollution-free green food. This product can also be used as a feed additive for feeding fish, cattle, pigs, etc.

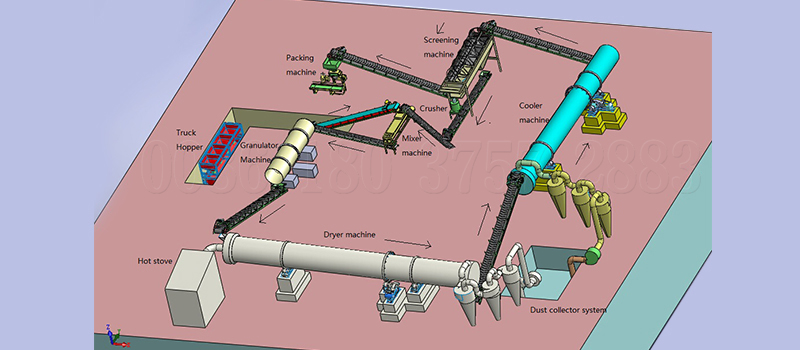

manure rotary dryer machine in organic fertilizer production line

The demand for chicken manure fertilizer drying equipment is huge, and it has a foothold in many fields. The chicken manure dryer is suitable for large, medium and small chicken farms and areas where the breeding industry is relatively developed. According to the requirements of drying products, it can be used Different heat sources. After filtering and eliminating old products, the era of high power consumption is gone forever. The new type of chicken manure dryer saves energy. This machine is suitable for chicken manure, duck manure, animal manure, slaughter scraps, etc. with a water content of less than 65%. It has a good effect on opening up feed resources, reducing feeding costs, and reducing environmental pollution. The chicken manure drying machine adopts airflow drying method, which has high thermal efficiency. It can complete deodorization and insecticide sterilization of materials at one time without destroying the quality of the finished product. This machine can dry high-temperature materials below the initial moisture content at one time. The final content is less than 14%.