Organic fertilizer is the main fertilizer to improve crop quality and reduce environmental pollution. The organic fertilizer production line realizes the transformation of high-quality organic fertilizer by reprocessing manure, straw, agricultural wastes and other agricultural wastes.

The heavy use of chemical fertilizer has led to the decrease of soil organic matter content, the serious land consolidation, the increase of crop diseases and the serious yield reduction. Organic fertilizer has no pollution and high fertility in agricultural production and use. Organic fertilizer is the main fertilizer used in agricultural production, which has the characteristics of long-term and lasting effect, activating land, promoting plant growth and increasing yield. Organic fertilizer production line mainly transforms waste into organic fertilizer through fermentation composting and granulation.

Fermentation composting is the first step of organic fertilizer production line. Fecal straw was put into fermentor for high temperature fermentation. After high temperature treatment, bacteria, insects and eggs were removed from compost. The organic matter after fermentation is sent to the equipment of organic fertilizer production line for granulation. Combined application of organic fertilizer and chemical fertilizer can complement each other and improve fertilizer utilization rate.

Chemical fertilizer is a quick acting fertilizer with high nutrient content, less composition and fast release, while organic fertilizer is a long-term fertilizer with high nutrient content but low relative content and slow release. In order to maintain the self-sustaining of nutrients and soil fertility, and strengthen the recycling and reuse of soil nutrients, in the organic fertilizer production line, organic fertilizer and chemical fertilizer can be combined to make organic-inorganic compound fertilizer, which can complement each other. The combination of fertilizer efficiency is more conducive to the absorption of crops, providing nutrients for crops and improving fertilizer utilization rate.

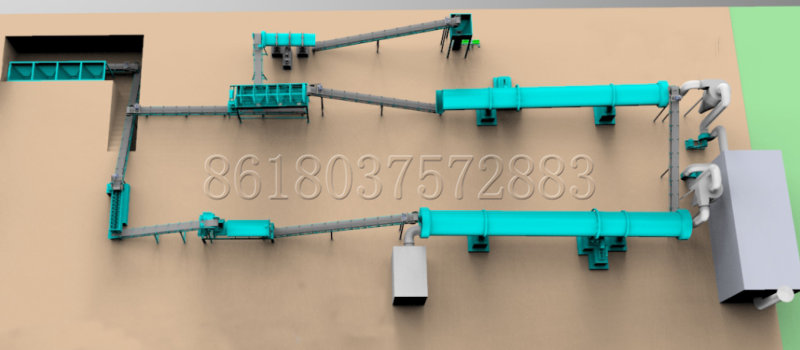

Using two in one organic fertilizer granulator, various organic fertilizers and chemical fertilizers can be mixed and granulated to produce high-quality organic fertilizer. Our factory has designed a large output organic fertilizer production line. The organic fertilizer production line mainly includes two in one granulator, ball mill, drum screening machine, vertical crusher, double shaft mixer, rotary dryer, rotary cooler and packaging machine. Through the deep processing of these equipment, organic matter can become high-quality organic fertilizer.

More details, go to https://organicfertilizerplants.com/