In recent years, the global NPK compound fertilizer market has seen tremendous growth, because people are increasingly aware of the urgency and necessity of balanced fertilization, and the development of NPK compound fertilizer production technology and formula has also played a certain role. In addition, NPK compound fertilizers usually have more premium space than single fertilizers. Therefore, many manufacturers put NPK compound fertilizers with more premium space than single fertilizers. Therefore, many manufacturers have included NPK compound fertilizers in their product portfolios.

The common granulation technology of compound fertilizer includes drum granulation, disc granulation, spray granulation, tower granulation and so on.

The high-tower nitrate rotating granulation method produces high-concentration nitro compound fertilizer. This technology sprays nicotine, phosphorus and potassium melts from the top of the tower, cools and agglomerates into granules during the landing process. In ammonium nitrate production enterprises, the use of high tower melting granulation method to produce compound fertilizer has the following advantages:

First, it can directly use concentrated ammonium nitrate solution and crushed solid ammonium nitrate for crushing to produce compound fertilizer. This operation simplifies the production process and ensures production safety.

Secondly, the melt rotating granulation process makes full use of the heat energy of the ammonium nitrate concentrate, the moisture content of the material is very low, and the drying process is not required, which greatly saves engineering consumption.

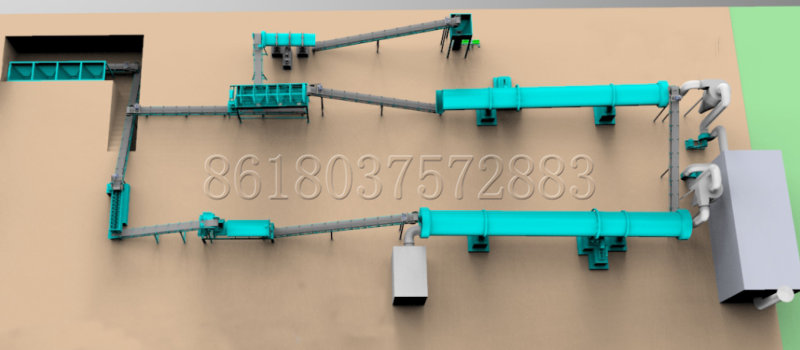

Drum granulator is the most widely used compound fertilizer processing equipment in compound fertilizer production. The formula limit is relatively small, and partial ammoniation can also be used. For most types of equipment, the production line can use 2-3 million units, the daily output is more than 280-400 tons, and the formula is more than 500 tons. Due to the small formula limit, high output, low investment, short construction period and other advantages, drum granulation technology is favored by many compound fertilizer manufacturers. And it is adopted by more and more compound fertilizer manufacturers. Using this method, we can use a drum granulator to complete the production process.

FPC independently develops and produces a complete set of fertilizer equipment such as fermentation equipment, drying equipment, granulation equipment, screening system, and batching system suitable for the production of organic fertilizer and bio-organic fertilizer. Welcome to visit our official website. https://www.fertilizerplantcost.com/npk-fertilizer-plant-cost/