The small scale organic fertilizer equipment production line can be either a powdery organic fertilizer production process line or a granular organic fertilizer production process line. Among them, the powdery organic fertilizer process line is a component of the granular organic fertilizer process line. Generally speaking, organic fertilizer production lines with an annual output of 20,000 tons (including) and organic fertilizer equipment production lines with an annual output of less than 20,000 tons are all small-scale organic fertilizer production lines. According to the plans of most customers, the small-scale organic fertilizer production line basically has several major production lines with main production capacities of 5,000 tons, 10,000 tons, 15,000 tons, and 20,000 tons.

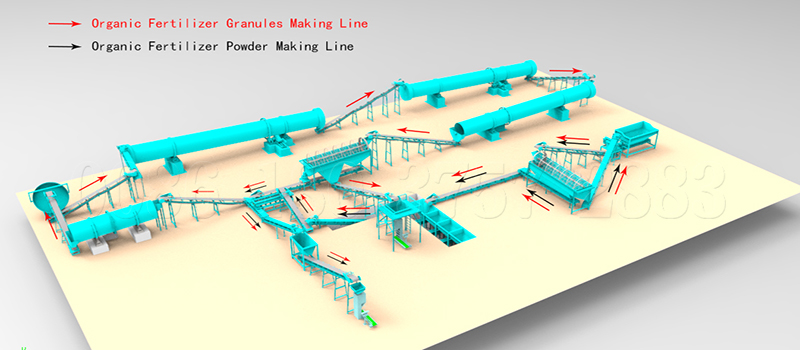

Granular and powder organic fertilizer production line

Since the powdery organic fertilizer equipment production line is a component of the granular organic fertilizer production line, today we will use the granular organic fertilizer production line to elaborate on the small scale organic fertilizer production line process. Know the process of the powdery organic fertilizer production line.

According to the process stage, the granular organic fertilizer production line is divided into ① crushing process; ② fermentation process; ③ stirring and mixing process; ④ granulation process; ⑤ drying process; ⑥ screening process; ⑦ coating process; ⑧ packaging process.

The process flow of powdered organic fertilizer includes the above-mentioned ① crushing process; ② fermentation process; ⑧ packaging process.

So, what conditions are needed to build a small-scale organic fertilizer equipment production line?

complete organic fertilizer production line

① The construction of small-scale organic fertilizer production lines must meet the requirements of environmental protection policies. Environmental protection is not only the aspiration of the people, but also the policy needs of the development of agriculture and animal husbandry for environmental protection;

②The source of raw materials, the radius around the source of raw materials, determine your plant location, site investment, transportation investment, etc.;

③The type of raw materials, the type determines the detailed equipment used in each process stage, which affects the equipment investment price, etc.;

④The production scale, the annual output of the small organic fertilizer production line from 3,000 tons to 20,000 tons, determines the capacity requirements of the equipment, which affects the price, etc.;

⑤Recycling of resources mainly relies on the recycling and utilization of various agricultural wastes, such as first making fuel and electric energy raw materials, and using the biogas residue as organic fertilizer raw materials;

⑥Other uses of the small-scale organic fertilizer equipment production line process can be used as feed, etc.;

⑦Building site: It is necessary to determine the production site size and site size investment according to the planned production scale.