The turning depth of the chain plate turning machine is 1.8-2 meters, and the turning depth of the general rake-tooth turning machine is 0.6-1.5 meters. The chain plate turning machine occupies a small area and is more efficient.

Equipment advantages of chain plate turning machine: this chain type turning pile mixer has the advantages of high crushing efficiency, uniform mixing, thorough pile turning, and long moving distance. New type chain plate compost turning machine has compact structure and advanced technology. It uses some beneficial microorganisms to promote the rapid decomposing of organic waste such as livestock and poultry manure. It adopts unique pond continuous aerobic fermentation technology to make organic waste. The materials are quickly decomposed, dewatered, sterilized, and deodorized to achieve the purpose of harmlessness, resource utilization and reduction treatment, low energy consumption, and stable product quality.

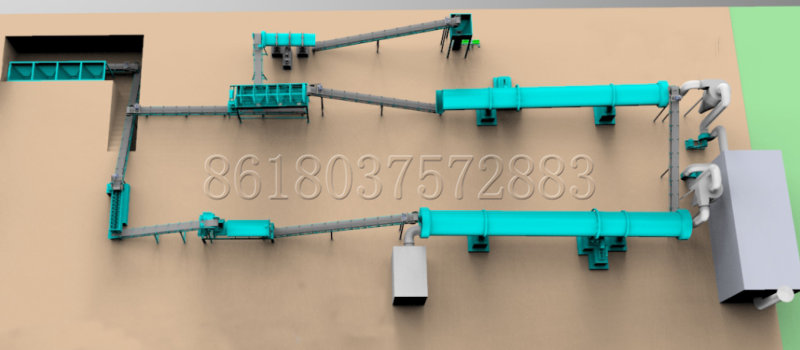

Installation and commissioning of chain plate type stacker machine.

- After all the parts of the chain conveyor equipment are installed and assembled, we need to fix the conveyor chain plates in place to ensure that the legs, columns, and platforms of the conveyor are fixed with chemical anchors. This step is very important. The work is safer only when the equipment is relatively stable, so we must carry out this work well.

- After the last step of the chain conveyor is completed, we should not slack, but also check all the bolts in general, do a thorough fixation to ensure that each screw is fixed. If there is a screw that we do not fasten well, it may cause safety hazards.

- The axis of the chain conveyor, the drive roller and the reversing roller must be vertical to the vertical center line of the frame, otherwise it cannot rotate flexibly, so these three items must be checked clearly , This is also a very important one.

- The chain conveyor should check the tension of the conveyor chain. If the tension to be checked, we need a set of data. The tension should be 1% to 1.5% of the captain. In the meantime, this is more appropriate. We need to keep this data well. If it is out of this range, we have to adjust it in time.

- The chain conveyor has a rope pull switch to be installed on one side of the equipment, and a steel wire rope should be connected between the two switches, and the tightness can be adjusted by yourself.

- There is also a switch on the chain conveyor, which is a deviation switch, which can be installed on both sides of the head and tail, and it is also installed in pairs. The specific position can be according to the instructions.

There many organic compost turner machine in FPC. Welcome to our website for ideal fermentation machine. https://www.fertilizerplantcost.com/chain-plate-type-compost-turner/