Producing fertilizer is an intricate procedure that will need a production line adequate to suit your needs. These will be different sizes, with some other capacities, for producing fertilizer of varying capabilities. Commercial compound fertilizer production lines are one of the most prominent. They allows you to fertilize your own crops, in addition to provide additional fertilizer pellets for other businesses. If you want to find one, you must consider all the various components that make them up. Finally, you must obtain one coming from a reliable source which offers them for good prices. They are tips that can be used to obtain the best commercial compound fertilizer production line in the marketplace.

Exactly What Are These Able To Perform?

Since the name would indicate, they produce good compound fertilizer. This is a fertilizer that will comprise of two or more separate components. It is possible to produce NPK fertilizer that is utilized worldwide to enhance the caliber of the soil. It can be only possible to produce this material in mass quantities if you have a professional compound fertilizer production line. It can include components that can crush the raw materials, converting it into powder, thus it may go via a granulation process. If you do set up a huge unit in your facility, you may expand your company or promote your usage of neighboring businesses.

The Components Of Commercial Compound Fertilizer Production Lines

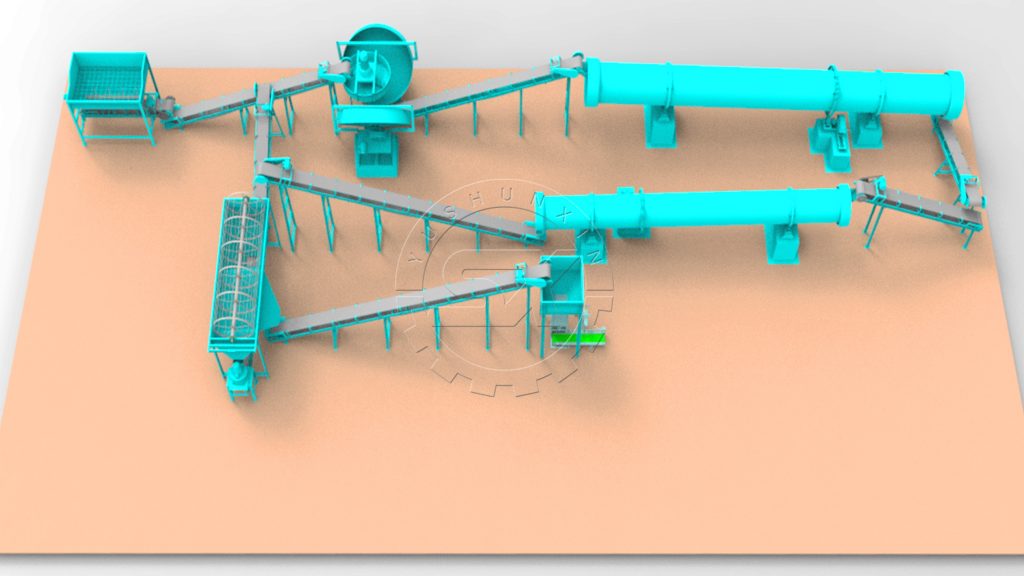

These are often positioned in a really specific order. You will find a preliminary system for crushing the raw materials. Second, you will have a mixer that will consider the powdered material, and combined it in specific ratios. The granulation process of compound fertilizer will be next which happens to be where material will probably be converted into pellets. These will subsequently be dried, cooled, and properly screened. After the screening process has ended, the packaging process will commence, allowing you to sell or store these pellets which have been made.

DIsk granulator for compound fertilizer

How To Locate Firms That Market These Systems

In order to discover the systems, it’s super easy to do. Online marketing is definitely the primary way that these manufacturers will obtain new business. Several of their existing customers will continually upgrade to the more improved systems that they are producing. Several of these systems can be extensive. You should consider the quantity of room which you have available at your facility. Finally, the cost of compound fertilizer making machines must be your final consideration. However, you really should consider paying extra for a bigger unit which can help you expand your company and capabilities.

Acquiring the right commercial compound fertilizer production lines is very important to your success. If this does contain all the components which were mentioned, it is going to be very efficient. The quality of this machinery, as well as its overall cost, has to be considered before making your choice. If you have not purchased one of these brilliant before, it might be advantageous to start looking today at what systems are offered. In case you have one of these inside your possession, it enables you to easily fertilizer crops and have excess amounts for storage.