How to make full use of organic waste resources is an important issue for China to build a resource-saving society, promote circular economy and develop organic agriculture. Organic fertilizer is one of them, organic fertilizer granulator is an essential equipment in organic fertilizer.

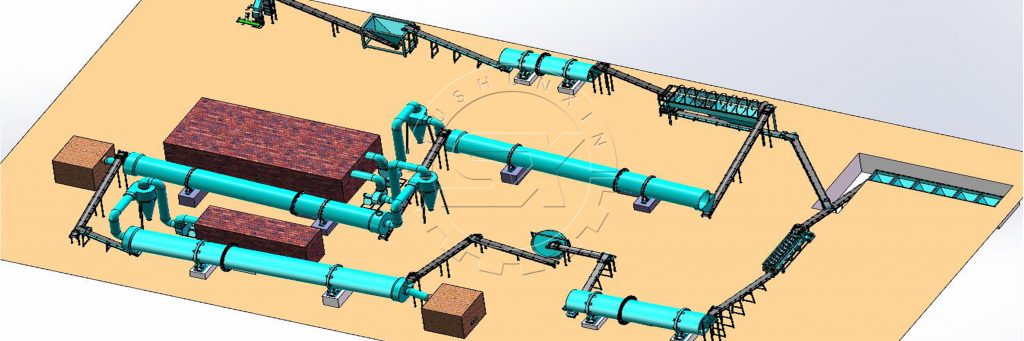

Granulator is a kind of forming machinery that makes materials into specific shapes. Organic fertilizer granulating system is a kind of granulator, used for granulation of various organic matter after fermentation. The following hui Hang machinery and you talk about organic fertilizer granulator.

Organic fertilizer particle

The granular fertilizer making machine commonly used in organic fertilizer equipment is: stirring gear pelletizer, disk pelletizer, compound fertilizer pelletizer, drum pelletizer

Agitating granulator is a kind of forming machinery which can make the material into a specific shape. The machine is composed of body part, granulating rotor part and transmission part. Wet continuous push rod granulation process is used to design and manufacture. Not only for a variety of organic matter granulation, especially for the use of conventional equipment difficult to granulate crude fiber materials, such as: crop straw, wine residue, fungus residue, pharmaceutical residue, animal feces, after fermentation can be granulated, but also for humic acid and municipal sludge and other raw materials granulation effect is also achieved very good results.

fertilizer granulating machine for sale

Teeth agitator granulator

The whole machine structure of the disk granulator is composed of large plate, big gear, transmission part, frame, base, scraper frame, no power scraper and other parts. Adopting the integral arc structure, the grain forming rate can reach above 93. There are three outlets, convenient for intermittent production, greatly reducing labor intensity, improve labor efficiency.

Disc granulator

Fertilizer pelletizer is a new technology, using two-way spiral countercurrent collisions granulation make organic material in the granulation can obtain continuous, high-speed, reciprocating amalgamated with shear, thus forming high pressure mechanical flow impinging stream, material temperature in the 20 s to more than 60 degrees, rapid change in the molecular structure of the material and granulation, heat transfer and flow between the materials, extrusion process was significantly improved, The granulation density and pelletizing rate are significantly improved, the energy consumption and template cost are greatly reduced, and the granulation efficiency is more than 50 percent higher than that of the traditional extrusion granulator. Because of high particle rate, smooth operation, strong equipment, long service life, and the majority of users choose as the ideal product.

Compound fertilizer granulator

Drum granulation machinery is one of the key equipment in compound fertilizer industry, which is suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizer. It realizes automatic scar removal and tumor removal, and cancels the traditional scraper device. The machine has the advantages of high ball forming strength, good appearance quality, corrosion resistance, wear resistance, low energy consumption, long service life, easy operation and maintenance, etc.

Drum granulator

China is a big agricultural producer and a big fertilizer consumer. Compared with chemical fertilizers, organic fertilizer has more obvious advantages. Green planting is also strongly advocated by everyone. Organic fertilizer granulator machine is an indispensable equipment for the production of chemical fertilizer.

organic fertilizer granulating machine