The process of compost production in the production of biological compost.

(1) The mixture of strains based on microbial fermentation was prepared.

In order to produce bio organic compost, the fermentation substrate must be used as the strain. We use HM fermentation base here. In order to make more evenly contact with chicken manure, 10 kinds of beneficial microorganisms, such as nitrogen fixing bacteria, nitrogen fixing bacteria, potassium decomposing bacteria, phosphate decomposing bacteria, yeast, actinomycetes, Bacillus Giganticus and Bacillus subtilis, are more evenly contacted with chicken manure, and 100g HM fermentation base material is divided into five equal parts. Every 20 grams, about 1-1.6 kg wheat bran or soybean meal and soybean meal are added to each HM fermentation base Other auxiliary materials, which are well mixed, are called plants. In this way, each bacterial mixture can ferment about 200 kg of chicken manure.

organic fertilizer large fermentation pot

(2) Two manufacturing methods:

The production of bio organic compost used in livestock and poultry manure can be divided into static processing and dynamic processing.

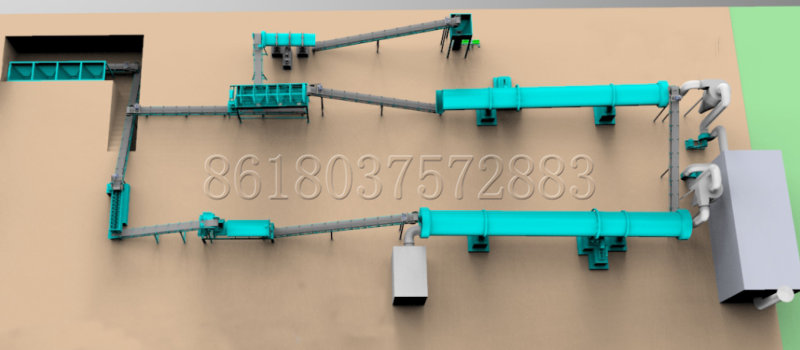

Bio compost production line

- static processing and manufacturing technology of bio organic compost:

Static treatment of bio organic compost is a kind of self-made bio organic compost produced by farmers in the field. The method is simple, easy to operate, and has less investment, which is suitable for small-scale professional farmers.

(1) Prepare chicken manure and accessories.

Choose an open space of about 30 square meters, flat ground, no water, and separate chicken manure from auxiliary materials.

In order to mix the mixture of strain and chicken manure evenly, we divided 1000 kg chicken manure into five equal parts. About 200 kg per serving.

Pan Granulation Compound Fertilizer Production Line

Generally, the grain or powder wheat bran, peanut shell powder and other main auxiliary materials, such as corn straw, cotton stalk, etc., must be cut into 5-10 cm long, too long will cause inconvenient mixing. The purpose of adding auxiliary materials is to regulate the water content and carbon nitrogen ratio of chicken manure and improve the permeability of fermentation materials.

(2) Fermentation platform construction.

After chicken manure and auxiliary materials are ready, fermentation platform shall be built according to the actual situation of environment and farmers.

When establishing fermentation platform, please select places with sufficient sunshine, flat, high terrain, avoiding opening of air outlets and easy to operate. First, some parallel ventilation ditches are excavated, with the width of 30 cm, depth of 30cm and width of ditch beam of 20cm. The branches, bamboo strips, straw and so on are spread on the ditch beam to form a fermenting platform with permeable bottom, which is convenient for ventilation and oxygen supply. Because the beneficial biota in HM fermentation base belongs to aerobic strain, the fermentation products can decay better only when there is enough oxygen.

After the fermentation platform is completed, we can continue to produce the bio organic compost which is still processed.

(3) Operation steps.

Evenly spread the mixture of the strain on the prepared chicken manure and mix well. During the mixing process, the moisture content of chicken manure should be adjusted to about 60%, namely holding several chicken manure in hand, holding tightly, and paying attention to the water between fingers, but not dripping water. Release your hand and gently touch to expand it. That’s enough water. If the water content is too high, add wheat bran, corn straw and other auxiliary materials to reduce the water content in chicken manure; if the water content is too low, add fresh chicken manure or sprinkle some water. Pile the mixed chicken manure on the fermentation platform.

The other four piles of chicken manure were treated in the same way, all piled together. At this time, the height is about 1-1.2m, the length and width are 1.5-2 meters, and the composting amount is generally 1.5 cubic meters.

(4) Management of fermentation process.

In the process of fermentation, temperature control is very important. If the temperature is too low, the mature standard cannot be met; if the temperature is too low, it cannot be reached. If the temperature is too high, the nutrients of compost are easy to lose. The temperature inside compost is from outside to within 30 cm. Therefore, the metal rod of thermometer used for measuring temperature must be longer than 30 cm. When measuring, it must be inserted into compost for more than 30 cm to accurately reflect the fermentation temperature of compost.

Fermentation temperature and time requirements:

After composting, chicken manure entered the first fermentation stage. It will automatically heat to above 55 ° C for 5 to 7 days, and then kill most parasite eggs and harmful bacteria to be harmless