In the complete set of equipment required for biological fertilizer production, fermentation stacker has gradually become a convenient tool to replace labor and forklift to deliver materials, and is the mainstream product of composting development trend with important influence.

According to the characteristics of organic fertilizer dumper, the characteristics used in composting production are: when making fertilizer, the dumper needs to adjust the carbon nitrogen ratio, pH and water content of raw materials, and some auxiliary materials must be added. add to. Depending on the lathe, the main raw materials and various auxiliary materials which are roughly stacked together in proportion can be evenly mixed to achieve the ideal granulating effect suitable for the granulator.

In the traditional stacker operation, the raw material particles are fully contacted and mixed with the air, and a large amount of fresh air can be cultivated in the stacker, which helps the aerobic microorganisms to produce spontaneous combustion fermentation heat and increase the stacking temperature.

When the temperature is high, adding fresh air to the reactor can reduce the temperature of the chimney. It forms the shape of high temperature exchange, and all kinds of beneficial microorganisms develop and reproduce in the appropriate temperature range.

The stacker system can process the material into small lumps, make the dense material pile loose and elastic, and form the appropriate porosity to promote the entry of oxygen.

After proper moisture fermentation, the moisture content of organic fertilizer is less than 40%. In the fermentation process, the biochemical reaction will produce new water, and the consumption of raw materials by microorganisms will gradually release water as carrier.

Therefore, in the process of fertilizer production, the water content is reduced in time. In addition to the evaporation caused by heat conduction, the raw materials are shifted from the stacker to form a forced water vapor distribution.

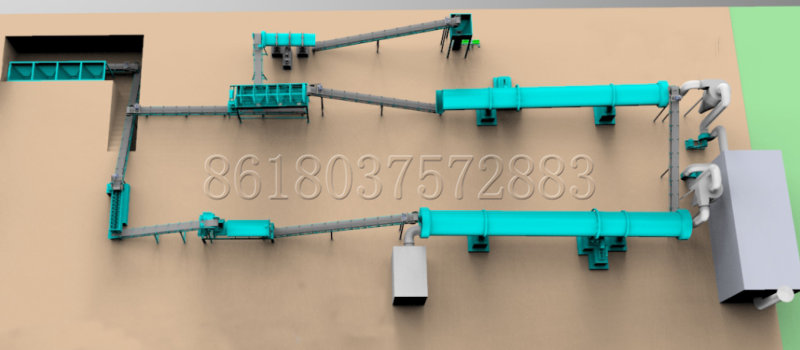

Our new organic fertilizer manufacturing equipment includes transverse device, walking device and stacking steering device. The stacking turning device consists of two reducers fixed on the frame, which are connected to the corresponding reducers through couplings and fixed with spiral blades. The utility model has the characteristics of improving the fermentation rate, rapidly decomposing the compost, preventing the generation of peculiar smell, and shortening the fermentation time.

eIt is usually applied to: farm, fertilizer fermentation, fertilizer factory, brewery, food factory and sugar factory fermentation of raw materials in fermentation waste fermentation and sugar residue crushing.