The granulator granulates better quality particles, users can external vacuum cleaner, meet the requirements of environmental protection.

This new two in one organic fertilizer granulator is used in the 200 t / D organic fertilizer combination granulation production line with a production capacity of 1-20 T / h.

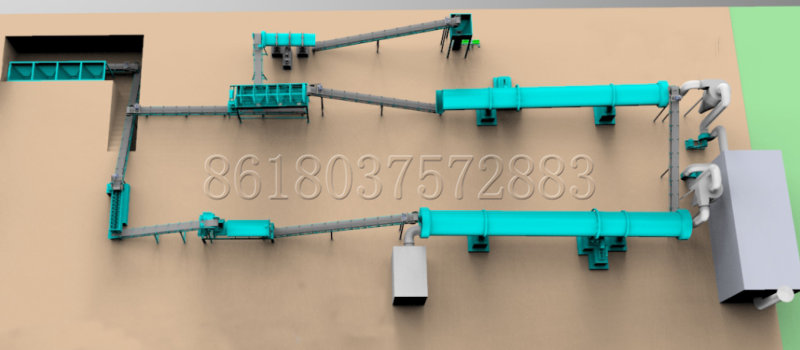

Pan Granulation Compound Fertilizer Production Line

It is a two in one granulator for organic fertilizer and compound fertilizer, so it is also used in the 200 t / D compound fertilizer combination granulation production line.

Its working powder is 42.6 to 80 kW, easy to clean the inner wall of the shell. Working principle: the material first enters the first granulation section from the uniform feeding section, and then is prepared for granulation through the high-speed adjustable mixing knife, and then pushed to the second granulation section.

Granulation material in the secondary granulation section, through the internal mixed teeth secondary granulation and outer cylinder forming, to achieve the purpose of granulation, so that the particles have better quality assurance.

We have designed the suction and discharge ports in the silo, users can connect the vacuum cleaner to meet the environmental emission requirements. We also designed the nozzles for observation doors and spray pipes. Users can spray liquid into the particles in the roller according to the particle size requirements.

More details, welcome go to https://fertilizergranulatormanufacturer.com/