China is a big agricultural country, so it is urgent to promote the application of bio organic fertilizer. Need the help of organic fertilizer granulator. At present, the soil on the land uses inorganic fertilizer for a long time, which leads to soil densification and fertility reduction, especially soil acidification. The shortcomings are already obvious.

Good organic fertilizer equipment can help farmers produce more and better bio organic fertilizer. It is very important to help the soil restore the natural ecological balance, which is mainly reflected in the following aspects:

(1) With the help of inorganic fertilizer equipment, chicken manure can be cleaned and transported at any time. Fresh chicken manure is processed by a series of inorganic fertilizer consuming equipment, such as composter, semi wet material crusher, mixer, dryer, etc. The second is to completely kill all kinds of pathogens in chicken manure, eggs, grass seeds and so on.

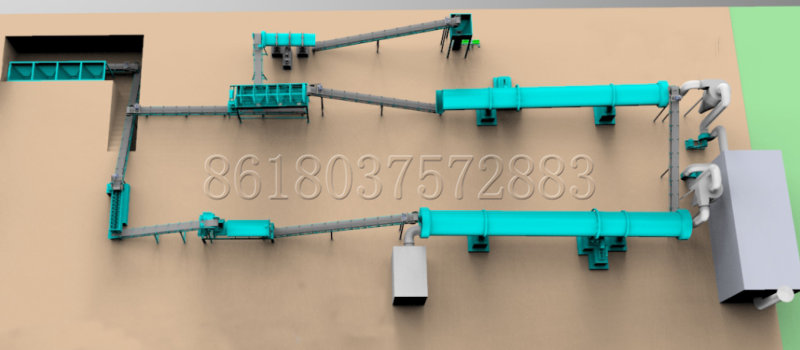

New Type Organic Fertilizer Production Line

The third is to remove the harmless substances in chicken manure, chicken residual drugs and avian influenza virus. In this way, the maximum increase in air purification and environmental, human, animal damage and loss.

(2) Faeces and faeces that are beneficial to human health are high in sulfur and ammonia, which can breed mosquitoes, flies and spread various diseases. After the disposal of inorganic fertilizer consumption equipment, it plays a corresponding preventive role in human life and well-being.

(3) As the export indexes of agricultural products exceed the standard, which indirectly affects the export of foreign agricultural products in China, the urgent task is to consume high-quality agricultural products and enhance the competitiveness in the international market.

(4) Increase the income of farmers and solve the employment problem of rich labor force. The inorganic fertilizer consumed by organic fertilizer equipment has changed the quality of agricultural products, improved the yield, brought higher income to farmers, solved part of the unemployment problem in China, and slowed down the pace of farmers’ becoming rich and wealthy.

China constantly advocates green food, pollution-free food and inorganic food, and advocates green environmental protection. The emergence of inorganic fertilizer consumption equipment provides a fundamental guarantee for such food in China, and also makes the use of inorganic fertilizer more and more widely. It is a health and well-being disease in China. Rapid development has made great contributions.

Production process of organic fertilizer:

In the organic fertilizer production line, different organic fertilizer granulators will be equipped. Organic fertilizer production line is different from NPK production process. Fertilizer mixers and fertilizer crushers handle raw materials. We can use chain crushers and horizontal mixers to process organic materials. In order to produce organic fertilizer granulator, fertilizer granulator must be equipped in the process of fertilizer manufacturing.

Bio organic fertilizer production line:

There, in the bio organic fertilizer production line, we can use the fertilizer granulator to complete the granulation process. We can design different types of fertilizer granulator, and we can choose the appropriate type of fertilizer granulator to complete the granulation process. More detailed info, welcome go to https://www.fertilizer-plants.com/bio-fertilizer-manufacturing/